The Netherlands, based in the Netherlands, is the most important tech company in human history. The semiconductor is not practically heard outside the industry’s passages, the company has created a machine – which has named the most ultra -violet (EUV) lithography system – which has made the development of modern microchops possible. Without it, the world will not see modern -day smartphones such as the iPhone 16 series and the Samsung Galaxy S25 series, the powerful GPUs of NVIDIA, or modern artificial intelligence (AI) models.

Five things you should know about ASML, which is the most important pillar of the Global Chip Supply China

ASML Overview

Established in 1984 as a joint venture between Philips and ASM International, ASML began a small place of lithography. For ignorance, lithography is the process of using light to “print” microscope samples on silicon wafers, which eventually becomes a chip that strengthens everything from smartphones and laptops to data centers, AI processors and fighter jets.

However, as the world was moving towards small computers, ASML began researching ways to print transistors, which were very low in size. In 1997, it first shifted its focus to EUV as an alternative to traditional lithography machines, which used deep ultra -violet (DUV) light. The DUV has a very small wavelength (about 13.5nm), which is around 193nm.

The benefits of euv lithography machines

EUV comes with a set of benefits. This technology allows machines to fit more transistors in one place, which allows rigorous periods, high efficiency, improvement of power consumption and small features. This technology also eliminated the need to use multi -patterning, which is more mistaken and expensive.

However, making EUV -based lithography machines is not easy. In fact, it is so difficult and expensive that it has taken more than two decades of efforts, several partnerships with companies working in semiconductor space, and billions of euros to build such a first system.

Technology behind ASML’s EUV lithography machines

Technology, to understand the complexities in the construction of euv lithography machines, must know this technology. According to IBM Research, a high power laser on the droplets of EUV light tons is shot and manufactured at about 50,000 times per second. Once the laser collisions, the ton becomes plasma, and this plasma emit the extremely ultra -violet light of 13.5nm wavelength.

It is said that this particular light is so dim that it can be absorbed with air or glass. This means that light has to travel in space using a mirror instead of a lens (because lenses are glasses that can absorb light). The ASML had nuclear -level smooths to make a curved mirror in partnership with Zeses and to focus the light on silicon waifers properly. Even a special thing of dust can completely throw the sample process. The light was then used to erect samples in the microchips, which will work as transistors.

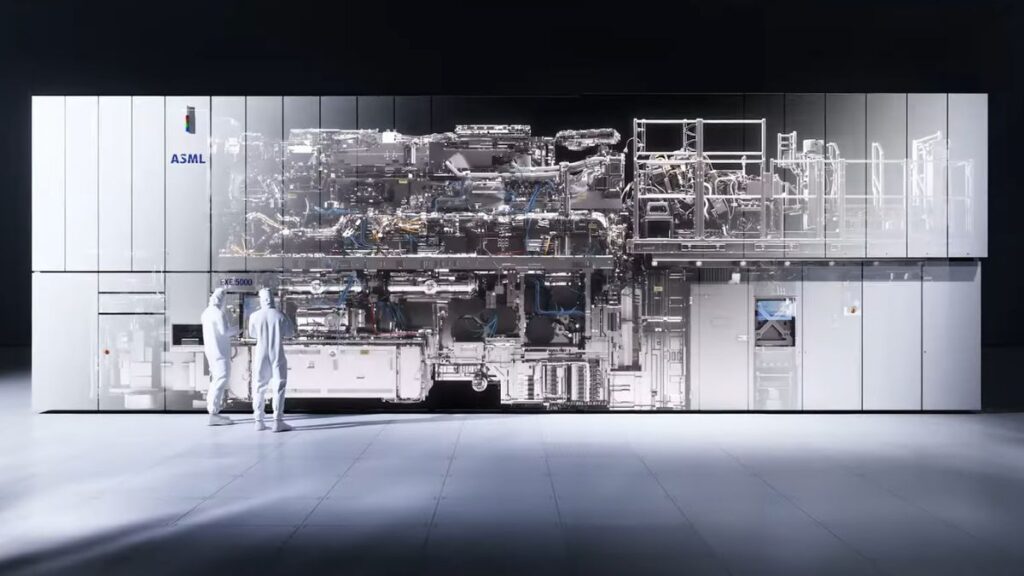

However, ASML’s success was not a lonely attempt. The company had the support of the Dutch government and spent 10 billion euros in more than 20 years to develop its first EUV lithography technology. In addition to partnerships with Zeus, ASML contributed with the US -based Cyrome (now part of the ASML) for the source of light, and Laser Amplirs, a German -based trumpet. Overall, the machine has 100,000 parts and it is the average bus size.

Why ASML is important

Due to these difficulties, even the world’s largest semiconductor companies, such as Intel and TSMC, refrain from producing their EUV lithography machines and instead provided them through ASML. Not only this, but also Samsung, both Intel and TSMC have invested in the company to help accelerate this research and create more advanced machines.

Today, ASML claims to be the title of the only company in the world that manufactures EUV lithography machines. It sells these machines for 350 million euros (about Rs 3,480 crore) such as a piece of companies like Intel, TSMC, Samsung and other chip makers. In particular, both Canon and Nicon produce DUV -based lithography machines, but they have not tried to move to EUV. This means that if anyone in this world wants to build a chip set with transistors below 7nm, they will have to buy machines from ASML.

The technology that led to a political dispute

Because of its unique status, the ASML has also been trapped in a political Cold War cross fire between the United States and China. In 2020, US officials pressured the Dutch government to deny the ASML export license for a Chinese company. As a result, the unit has never been sent to China, and to date, the Netherlands does not allow any Chinese buyer to export the machine.

As a result of this increase, China also publicly condemned the Dutch export policies and called it “unilateral bullying” and technical pressure. The country has also begun the domestic development of this technology. However, there is no report of success so far.