We have often said that the reason for the volatility in obtaining highly ultra -violet (EUV) lithography machines of Chinese foundries and tech manufacturers is that China’s chips are far behind in the race. Thanks to us and Dutch officials, a company that makes up advanced lithography gear, Dutch firm ASML, cannot send EUV’s latest lithography equipment to China. However, low -advanced deep ultra -violet (DUV) lithography machines can still be sent to China using old technology.

This is important because EUV machines are needed to manufacture chips under 7NM. Foundry like the TSMC and the Samsung Foundry will produce large chips this year using their 2 NM process nodes. The number of the lower process node means that the transactions used are small, which allows to fit into a small space inside the chip. This number is called transistor density and is usually shown as millions or billions of transistor per square millimeter. The higher the transistor density, the more powerful and energy -efficient chip.

The e -beam lithography machine of a native home can be the progress of making China quiet with the first film

The lithography machine is used to transfer the circuit samples on silicon wafers that act as the basis of the chips manufactured by the foundations. Deep Ultra Violet (DUV) Light wavelength is 193 nanometers. However, the EUV uses light with only 13.5 nanometers, which is about 14 times less. This small wavelength allows Euvs to stand out the fine samples needed for today’s complex chip designs.

“Due to export controls, such equipment has long been out of access to leading domestic research institutes, including the University of Science and Technology and Jiang Lab, China.”

Daily Hangzho

But the Chinese have created their first e -beam lithography machine, titled Zezi. It was created at Jiang University in Hangzhou and uses electron beams to focus to stand the circuit samples on silicon waifers. The negative side is that e -beam lithography cannot produce large -scale chips such as DUV and EUV machines cans cans cans cans. But for China, when it comes to lithography, it is a port in the storm, and e -beam lithography works very well during the production testing phase.

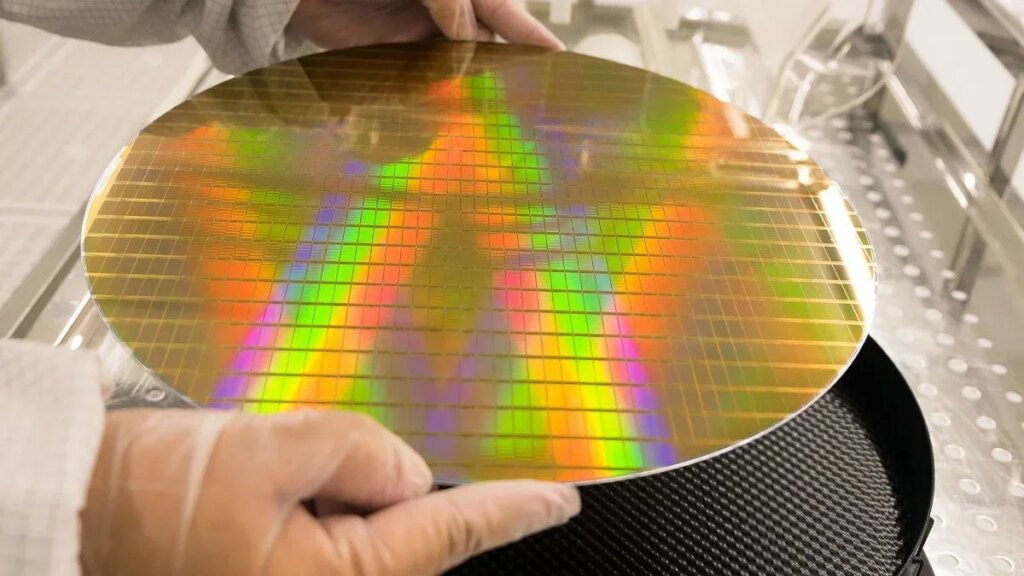

An ASML created a highly ultra -violet lithography machine. | Image Credit- ASML

A local newspaper, Daily Hangzhou“Due to export controls, such equipment has long been out of the access to leading domestic research institutes, including China’s University of Science and Technology and Jiang Lab, for a long time. The supply of XIHI is expected to help break the deadlock.” Zezi can narrow the circuit lines like 8 nm, whose positioning accuracy is 0.6nm. It meets international standards.

Interest with Chinese companies and the Research Institute has begun to take an interest in zesi. The domesticly manufactured e -beam lithography machine is cheaper than imported devices imported into China. It is just the beginning of China’s attempt to ignore US sanctions by developing its own chipmost equipment. There are reports that Huawei is working to build his EUV machine.

Huawei is allegedly testing its EUV Lithography Machine

According to reports, Huawei is testing the EUV machine trial in his factory in Guan. It is understood, Huawei’s aim will be aimed at testing with a mass production in 2026 later this year. Should Huawei be able to make an EUV machine, it will usually be a big deal for China and especially for Huawei. This could allow Huawei and China’s largest foundry, SMIC to produce modern chips that might compete with the American chip design, such as Apple, Qualcomm, and Navidia, designed by Navalia.

Before the United States enforced sanctions that prevent Huawei from receiving modern chips, the Chinese manufacturer’s Heslikan Chip Design Unit was the second largest TSMC user after Apple. At that time, Huslenkin and thus Huawei had access to the nodes of the TSMC’s most modern process. In fact, the last chip made for Heslikan before kicking US sanctions was TSMC Karen 9000 AP. Made using TSMC’s 5NM process node, it was the SOC that used the Huawei Mate 40 series in 2020 for strength.

Following the implementation of the sanctions, Qualcomm was granted a US Trade License, allowing him to send 4G Snapdragon chips to Huawei. In 2023, Huawei stunned the industry by issuing a Met -60 Series operated by 9000s. Developed by SMIC, the SOC Foundry’s 7NM process node was built using the 7NM process node and returned 5G support on the Huawei flagship phone.

Read the latest from Alan Fredman